Survey Matters – March 2025

- High volume of applications expected for renewal of marine surveyor accreditation – Plan ahead!

- Certificate of survey (CoS) and certificate of operation (CoO) requirements for domestic commercial vessels (DCVs)

- Marine safety incident – Person overboard

- New Exemptions

- Safety recall notice

- Proposed GES to allow ISO 12215 for vessels up to 24m

- Bringing a new build domestic commercial vessel into Australia: Key requirements

- Summary of Audits 2023-24

- Reminder – have your say on the surveyor accreditation scheme

- Survey Matters suggestions

High volume of applications expected for renewal of marine surveyor accreditation – Plan ahead!

We are expecting 106 applications to renew marine surveyor accreditation in 2025. This peak occurs every five years.

Ensure your application is complete and meets the requirements for renewal. An early application will ensure that your accreditation does not expire. The Marine Safety (Domestic Commercial Vessel) National Law Regulations 2013 specifies that a renewal application must be made at least 3 months prior to expiry of your accreditation.

Key Information

Think about the application and supporting documents

- Considering the higher volume of application expected this year, we recommend preparing your supporting documents as early as possible

- Check the expiration date of your accreditation and expect a courtesy reminder from AMSA (Accreditation team) four months prior

Application AMSA804 form – familiarise yourself with the form

Supporting Documents

Continuing Professional Development (CPD)

Ongoing professional development is a requirement to maintain your accreditation. Utilise any CPD you have or are currently undertaking with a professional association related to vessel survey, design, building or engineering. AMSA requires evidence of CPD to support your application. Some examples may include:

- Statement of continued professional development (CPD) from your professional association;or

- Copies of certificates relating to:

- additional qualifications you may have attained since your initial or subsequent accreditation

- short courses/safety training

- technical meetings/conferences/workshops

- mentoring

- written publications (e.g., subscriptions to magazines)

- webinars relevant to marine surveying

- survey work outside of national law; or

- completing online courses related to marine safety regulations

Evidence of current professional association membership relevant to surveying. Some examples are:

- AIMS stamp showing membership level and expiry date

- RINA letter confirming class of membership and expiry date

- IIMS membership card and expiry date

- IMarEST membership card and expiry date

NOTE: A tax invoice alone is insufficient, as it does not provide proof of payment, membership details, or the membership expiry date.

One photograph of yourself, taken within the last six months:

- with dimensions of 45mm x 35mm (not including a border)

- face centred from the neck up

- passport photograph taken at any Australian Post office will be preferred (if possible)

- white background

- scanned in high resolution of 300-600dp

Relevant fee

- Current fee as of 1 July 2024 is $317, however the fee will increase on 1 July 2025 when the annual indexation is applied

Where to send the application and supporting documents?

- A courtesy email will be sent four (4) months prior to expirationof marine surveyor accreditation by the Accreditation team

- Upon receipt, note the due date of submission

- Start to collate the abovementioned supporting documents and reply by return email to: dcvsurvey@amsa.gov.au

Certificate of survey (CoS) and certificate of operation (CoO) requirements for domestic commercial vessels (DCVs)

What is the issue?

Despite an extensive education campaign undertaken at the start of the National System, AMSA Marine Inspectors are continuing to see domestic commercial vessels operating without a CoO (or exemption from CoO) when conducting inspections. There are also DCVs being operated without a CoS (or exemption from CoS) but holding a CoO. In some cases, the certification has expired, and in other cases, the vessel has never held the required certification.

Aside from an inspection by an AMSA Marine Inspector or compliance partners, often the only interaction an owner has with the National System is when they have their vessel surveyed by an Accredited Marine Surveyor (AMS). As such, AMSA is requesting assistance from the AMS community to help raise awareness of the owners' obligations under National Law. Note that this assistance is entirely voluntary.

What are the rules?

Under the National Law , operators must conduct their business using safe vessels and have safe systems of work embedded in their operations. Operators must hold current CoS and CoO as per Marine Order 503 and Marine Order 504, unless exempt.

Some non – survey DCVs operate under exemptions (e.g. Exemption 2 or Exemption 40) which exempt them from holding a CoS. However, depending on the exemption being applied, they must hold a non-survey permit, an Exemption 40 permit or, if they are a grandfathered "existing vessel” under Division 5 of Exemption 2, they will only require a CoO.

DCVs can operate without a CoO if they meet the criteria of Exemption 3 under Marine Order 504.

What can happen?

AMSA’s foremost concern is for the safety of people, property and the environment. Operators are required to ensure their vessel complies with the law and is operated safely.

AMSA Marine Inspectors can issue breach notices that result in penalties to operators found to be operating without the required certification.

What can an AMS do to help raise awareness with operators?

- When conducting surveys, advise the operator of their obligation to have a Certificate of Operation (if applicable). In most cases, if a vessel has a Certificate of Survey or an Exemption 40 permit, it will also need to have a Certificate of Operation.

- Show the operator how to access information on the AMSA website or contact AMSA Connect.

- AMSA Connect operators are available from 8 am to 5 pm Monday to Friday AEDT by calling 1800 627 484or emailing AMSAConnect@amsa.gov.au.

Marine safety incident – Person overboard

A near miss incident recently occurred on a passenger ferry operating on Sydney Harbour. While the vessel was underway, a passenger moved to the starboard upper deck to take a photograph. As the passenger leaned on the bulwark gate for support, the gate detached from its mounts and fell overboard.

The passenger partially fell through the bulwark feet first but was able to regain footing on the drainage gutter at the edge of the superstructure, preventing a complete fall from the vessel. The passenger promptly pulled themselves back onto the upper deck and sustained only minor injuries, requiring no medical treatment beyond basic first aid.

The detached gate fell into the water approximately three metres from the lower aft deck, where other passengers were present.

In response, the operators immediately secured the area and installed temporary barriers. The incident was reported to the Australian Maritime Safety Authority (AMSA), and the operator conducted an internal investigation in coordination with AMSA to determine appropriate corrective actions.

Investigation and findings

Inspections and investigations conducted by the operator revealed that the forward upper hinge pin was missing, and the hinge plate was bent. This evidence suggests that the hinge pin either failed or was not adequately engaged with the hinge pivot. Consequently, the failure of this hinge allowed the gate to detach from the remaining mechanisms and fall overboard.

|  |

The operators and AMSA’s investigations identified that the incident was likely due to a combination of factors related to the design and maintenance of the gate:

- Usage and Inspection: The upper deck gates on this class of vessels had not been operated since construction and were treated as fixed panels rather than functional components.

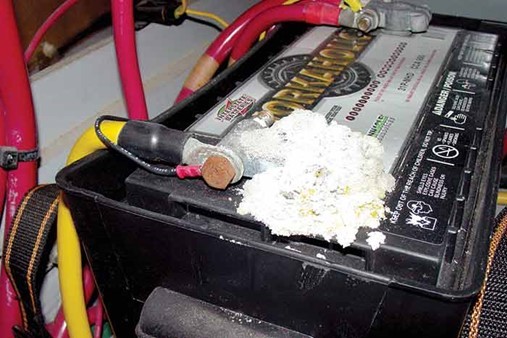

- Potential Corrosion and Material Fatigue: The hinges, made of dissimilar metals, likely experienced corrosion, weakening their integrity. A spring-loaded pin designed to handle outward loads may have been compromised due to wear or failure.

- Design: The inward-opening gates lack a physical stop or catch to prevent outward movement, making the hinge and pin mechanism vulnerable to stress.

The operator was not aware of the condition of the gate securing arrangements. It is probable that the dissimilar metals had failed at an inopportune time. The stainless-steel hinge was mated to an aluminium bracket which after time may have weakened until it gave way.

The operator has implemented an increased inspection and maintenance regime for these gates and has commenced a redesign of the hinge and closing mechanisms.

Previous incidents

This incident has similarities to that published in the December 2021 edition of Survey Matters. Since the publication of the article there have been at least three further incidents of a similar nature on Sydney Harbour alone.

Key takeaways

Surveyors are reminded of the potential for accelerated corrosion between dissimilar metals, which may be present in bulwark gate hinges and closing mechanisms. Given that bulwarks, gates, and railings play a critical role in ensuring the safety of passengers and crew, it is essential to thoroughly inspect the condition of access gates, hinges, and closing mechanisms during surveys. Any safety concerns identified should be promptly communicated to the Owner and Master, with defects requiring immediate rectification.

New Exemptions

AMSA is introducing new exemptions to provide a simplified process for certain vessels to obtain a certificate of survey and operate as Domestic Commercial Vessels (DCVs), including vessels with minor non-conformances or vessels built to Navigation Act 2012 requirements.

The exemptions cover the following scenarios:

| Exemption instrument | Scenarios |

|---|---|

| Updates to Exemption 07 – Marine Safety (Temporary operations) Exemption 2024 (EX07) | A vessel with minor non-conformances that has been identified during an initial or renewal survey, but which is safe to operate. An existing vessel that has ‘triggered’ the transitional vessel provisions in Marine Order 503 (MO503) but is not yet compliant with the transitional standards in MO503. |

| NEW Exemption 49 – Marine Safety (Domestic commercial vessels — compliance with international standards) Exemption 2024 (EX49) | A vessel built to Navigation Act 2012 (Navigation Act) requirements This may be a regulated Australian vessel (RAV) that is transitioning to be a DCV, or it may be a new vessel built to RAV requirements which always intended to operate as a DCV. |

The updates to EX07 enable transitional and non-transitional vessels to continue to operate up to a maximum period of 12 months (when using the applicable division), while undertaking work to rectify non-conformances with the applicable standards in MO503. The exemption is only available where a surveyor has conducted an initial or renewal survey and considers that any non-conformance will not jeopardise the safety of the vessel or any person on board the vessel. An approval is required from AMSA and a surveyor must provide a survey report that meets the criteria in the exemption. For more information, please see sections 6 and 7, Division 2, of the updated EX07 here Exemption 07.

The new EX49 introduces a simplified process for vessels built to Navigation Act requirements to operate as DCVs, provided the vessel continues to meet the requirements that would apply if operating as a RAV, including the standards of the vessel’s classification society. Operators do not need approval for this exemption but will need to meet the eligibility conditions and apply for a certificate of survey. For more information, please see the new EX49 here Exemption 49. Surveyors are encouraged to review the exemptions which commenced on 1 March 2025.

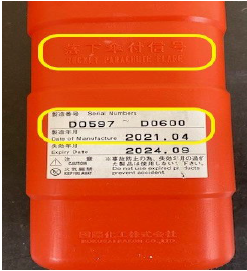

Safety recall notice

The intention of this notice is to provide surveyors with important updates in relation to the following safety recalls. Please ensure you are aware of equipment recalls when undertaking surveys where these items are present.

Safety recall: Halkey Roberts 3F Single Point Manual inflators in lifejackets

Issue

Faulty “V96000 Halkey Roberts” manual inflators are installed in the following lifejackets:

- Life Jacket Solutions (LJS) – Model numbers T150M, G150M, B150M, WB100, PR150M, SRSS150

- Marlin – Model number MK150

The indicator status on the inflator may show the life jacket is ready for use even when the attached gas cylinder is empty, removed or not connected properly.

Hazard

Risk of drowning if the lifejacket does not inflate as expected when the manual inflator is deployed.

Identification

The grey plastic part of the inflator indicates a recalled product.

Recalled inflators are marked “V96000 Halkey Roberts ®” and have a manufacture date between 4 June 2021 and 15 April 2024 (this will be laser printed in the format MM/DD/YY).

V96000 Halkey Roberts Inflator

For further information please click on recall fact sheet and product recall page links above.

Surveyors’ responsibilities

- Notify the operator of the recall.

- Forward recall information to the client.

- Document non-conformances if recalled inflatable lifejackets are found on board during inspection.

- Communicate these findings to the vessel operator and AMSA (AMSA586).

Safety recall: Rocket Parachute Flares KP-16

Issue

Kokusai Kakoh company has issued a safety recall for its Rocket Parachute Flares KP-16. This is due to performance concerns related to altitude and burning time when fired.

Identification

- Checkif KP-16 flares manufactured between February 2021 and July 2024 are carried as part of safety equipment.

- Advise operator to contact nearest Comet distributor for a free replacement with Comet Red Parachute Signal Rockets.

|

|

For further information please click on recall fact sheet and product recall page links above.

Surveyors’ responsibilities

- Notify the operator of the recall.

- Forward recall information to the client.

- Document non-conformances if recalled inflatable lifejackets are found on board during inspection.

- Communicate these findings to the vessel operator and AMSA (AMSA586).

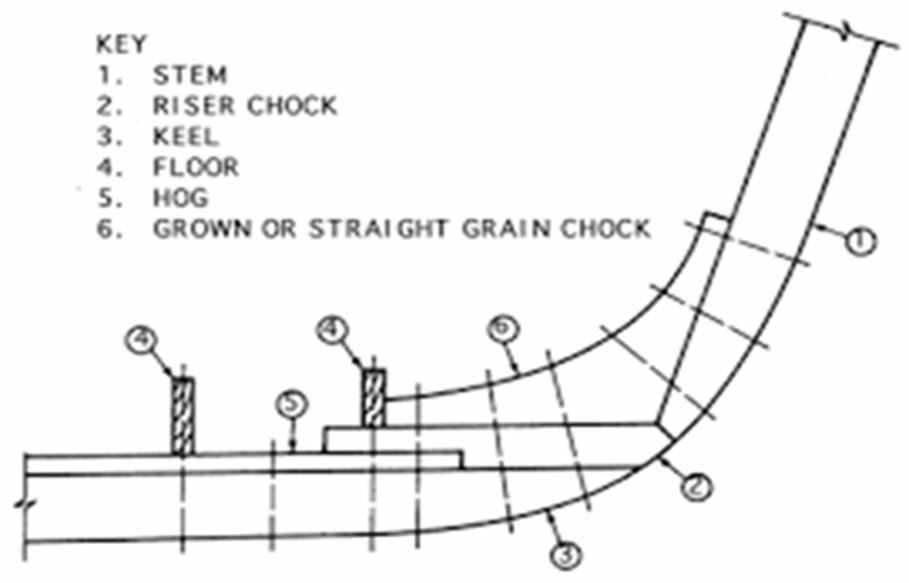

Proposed GES to allow ISO 12215 for vessels up to 24m

- In Australia, the National Standard for Commercial Vessels (NSCV) specifies the technical standards for Domestic Commercial Vessels (DCVs). Within this suite of standards, Part C Section 3 Design and Construction specifies the standards for construction of vessels.

- Currently, the deemed to satisfy solution for determination of scantlings in NSCV C3 allows the use of ISO 12215 as an alternative to the Lloyd’s Register Class Rules, however only for vessels up to 13m length in ‘light operations’.

- The 13m length in ‘light operations’ limit was imposed due to the risk that ISO 12215 was not complete at the time of drafting the NSCV C3 and ISO 12215 was meant for recreational vessels only.

- It has been over 10 years since the introduction of the NSCV C3 and a review of these limitations is warranted due to the following reason.

- ISO 12215 is for vessels up to 24m

- ISO 12215 has evolved over the years and is now applicable to both recreational and commercial vessels

- At its first major review in 2019, a new annex called Annex J has been introduced with additional requirements for commercial vessels

- ISO 12215 has been used for DCVs under 13m without issues

- AMSA has more understanding and experience using ISO 12215

- AMSA regularly receive specific exemption applications for vessels over the 13m limit

- The fastest way to implement this type of update to the NSCV standards is using a Generic Equivalent Solution (GES). The NSCV requires that equivalent solutions must comply with the required outcomes of the standard and are at least as effective as the deemed-to-satisfy solution. In this case, it has demonstrated compliance with the nine (9) required outcomes in Chapter 2 of NSCV C3 and similar effectiveness as the deemed-to-satisfy solution in Chapter 3 and 4 of NSCV C3.

AMSA is currently assessing if ISO 12215 with Annex J can fulfill the above criteria so the 13 m length limit can be removed and determine if “robust operations’ are allowed. A wide range of Class 1, 2 and 3 vessels expecting to operate in B, C, D and E waters will benefit if both can be achieved.

If AMSA assessments indicate that only the 13m limit can be removed, most of the work boats will still be excluded as they will fall into the ‘robust operations’ category.

- The goal of our assessment is to determine whether it is equivalent to the deemed to satisfy solution in NSCV.

How you can help

- If you have any suggestions, supporting evidence or information that you would like to share, please email to dcvsurvey@amsa.gov.au with the email subject ‘Suggestion/info for ISO 12215 GES”

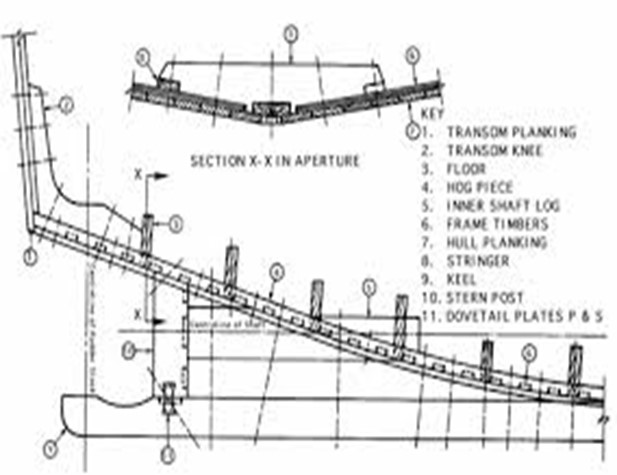

Bringing a new build domestic commercial vessel into Australia: Key requirements

Do you have clients planning to build a vessel overseas and bring it into Australia to operate as a Domestic Commercial Vessel (DCV)? If so, several key factors must be considered before the journey to ensure a smooth transition into the national system. These include:

- Timeline

- Vessel Certification

- Transit Requirements

- DCV Certification

1. Timeline

Bringing a vessel to Australia involves multiple stakeholders, extensive planning, and various certification checks. To ensure a smooth process, contact AMSA Flag state control team as early as possible providing details of the intended voyage. AMSA can offer specific guidance on regulatory requirements

Once contacted, AMSA will arrange a stakeholder meeting to discuss:

- Vessel’s specifications

- Proposed delivery method

- Applicable regulatory requirements

Holding this meeting early in the process allows all parties sufficient time to prepare and comply with relevant regulations.

2. Vessel certification

An Australian commercial vessel proceeding on an international voyage is defined as a regulated Australian vessel (RAV).

RAVs must be built and maintained in class and comply with Australia’s Marine Orders 1-97 and applicable international conventions. AMSA advises that owners engage a classification society that is one of AMSA’s recognised organisations (RO’s) at the plan approval stage to ensure compliance with class and statutory requirements.

AMSA acknowledges that smaller vessels may face difficulties meeting all requirements. In such cases, the owner may apply for an exemption, waiver or equivalence by submitting an application to AMSA that is reviewed and endorsed by the RO.

AMSA will review the application and determine whether an exemption, waiver or equivalence may be issued.

⚠ Note: If the vessel is being transported to Australia as deck cargo on a ship, it does not require certification as a RAV. Some requirements may not apply for a vessel being towed without any crew onboard. Please contact AMSA for further guidance. An alternative method of bringing a vessel to Australia is to have it registered and certified with a Foreign Flag. A foreign registered vessel arriving in Australia may be subject to Port State Control inspection.

3. Transit requirements

Several additional compliance requirements must be met before the delivery voyage:

- Registration on the Australian General Shipping Register

- All Australian vessels traveling to or from a foreign port must be registered.

- Asbestos Compliance

- Importing asbestos or asbestos-containing materials is strictly prohibited. Contact the Australian Border Force to ensure proper inspection and certification measures before arrival.

- Ballast Water Management Compliance

- The vessel will be subject to biosecurity controls and must report biofouling management through the Maritime Arrivals Reporting System before entering Australian waters.

- Minimum Safe Crewing Compliance

- The vessel must have a minimum number of crew based on its size. Crew members must also hold the necessary qualifications. Apply for a Minimum Safe Crewing Document through AMSA.

- ISPS Code Compliance (if applicable)

- If the vessel is a passenger vessel or cargo vessel of 500 gross tonnage or above, it must comply with the International Ship and Port Facility Security (ISPS) Code.

4. DCV Certification

Once the vessel arrives in Australia, it can transition from an RAV or Foreign-Flagged Vessel to a DCV, provided no further international voyages are planned.

The below outlines the required steps.

- Revoke statutory certificates

- AMSA can revoke RAV certificates, with the express written permission of the applicant.

- Foreign Flagged Vessels must consult their flag authority and provide evidence to AMSA that their registration has been cancelled and statutory certificates revoked. The vessel will also need to be registered with the Australian general shipping register if it is greater than 24m in tonnage length and capable of navigating the high seas.

- Complete the Certificate of Survey Application

- The vessel must meet DCV survey requirements. It is recommended that the person responsible for recommending the DCV survey codes in MARS surveys the vessel and submits the required forms as soon as possible.

- Survey work can begin while the vessel is still overseas and be finalised upon arrival in Australia.

- EX49 may also be used to bring the vessel into DCV survey, see above for more details.

Plan ahead for a smooth process

Bringing a new build DCV into Australia requires careful planning to meet regulatory and safety requirements. Ensuring compliance from the design phase will save time and costs, helping you set sail with confidence.

Need help navigating the process? Visit AMSour websiteA.gov.au for guidance or contact the relevant AMSA departments below:

✉ FSC@amsa.gov.au – Flag State Control (International voyage queries)

✉ DCVSurvey@amsa.gov.au – Vessel Safety Unit (DCV-related queries)

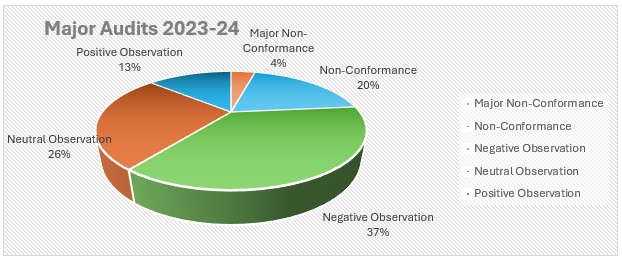

Summary of Audits 2023-24

Major Audits 2023-24

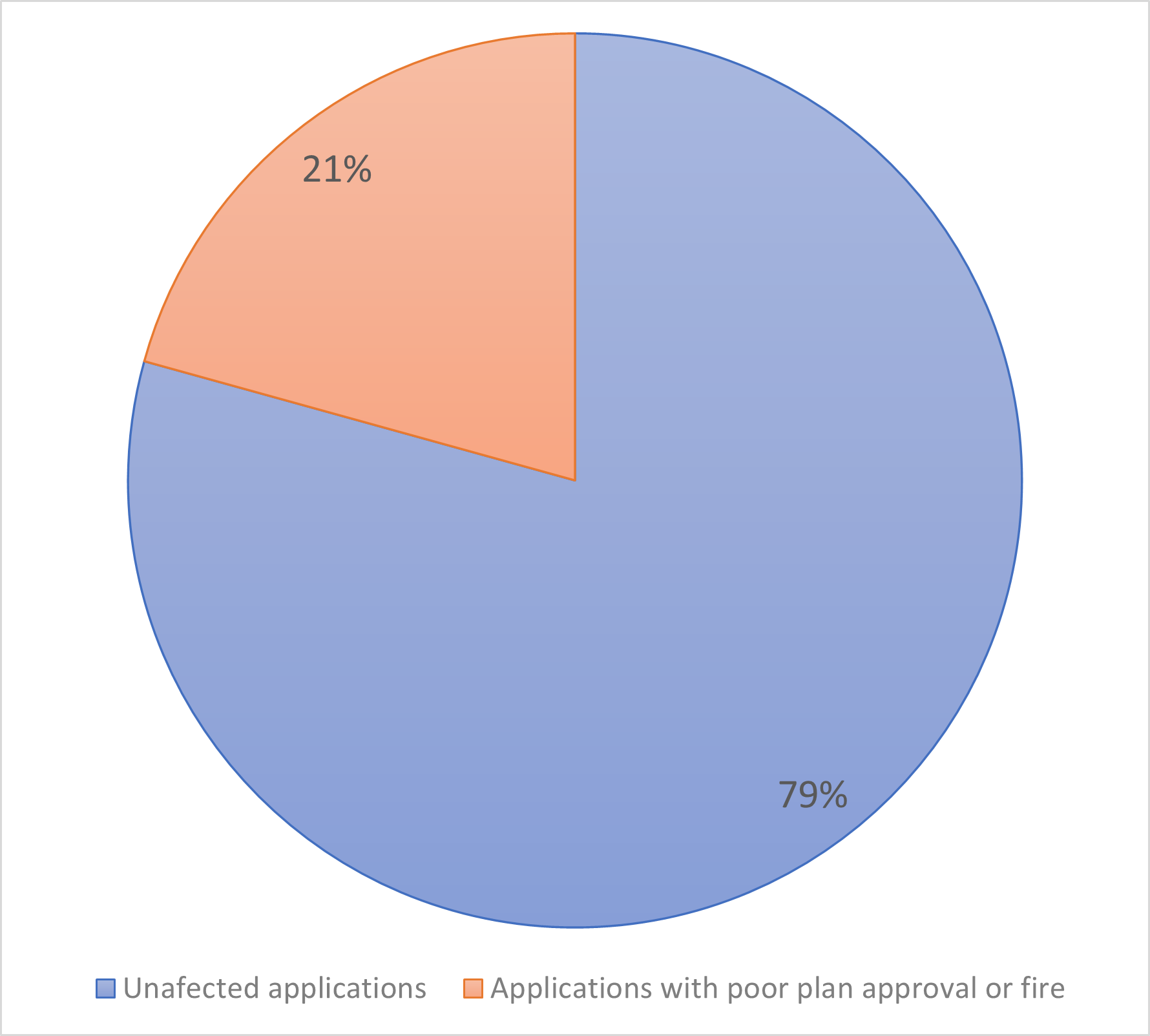

During the financial year 2023-24, AMSA carried out major (scheduled) audits on 188 survey recommendations covering 28 accredited surveyor audits. The 28 surveyors were selected for the audits using AMSA’s surveyor risk rating tool.

Additionally, AMSA performed 21 audits based on feedback received from a member of the public or an AMSA Staff member affecting 13 Accredited Marine Surveyors (AMS). One surveyor was requested to show cause as to why their accreditation should not be suspended due to the failure to comply with a condition of accreditation referred to in Division 3.3 of the Marine Safety (Domestic Commercial Vessel) National Law Regulation 2013 (the regulations).

On-site monitoring surveys were also performed on 3 surveyors.

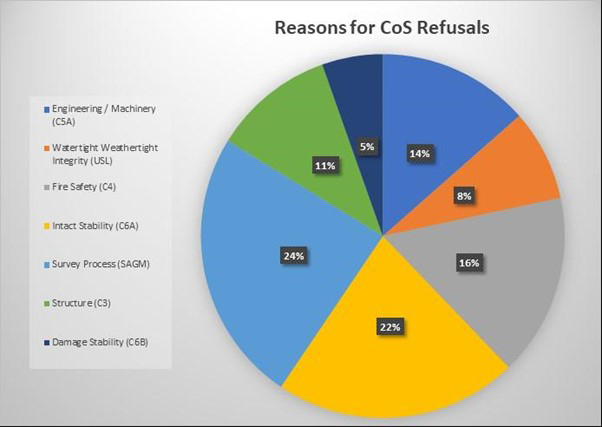

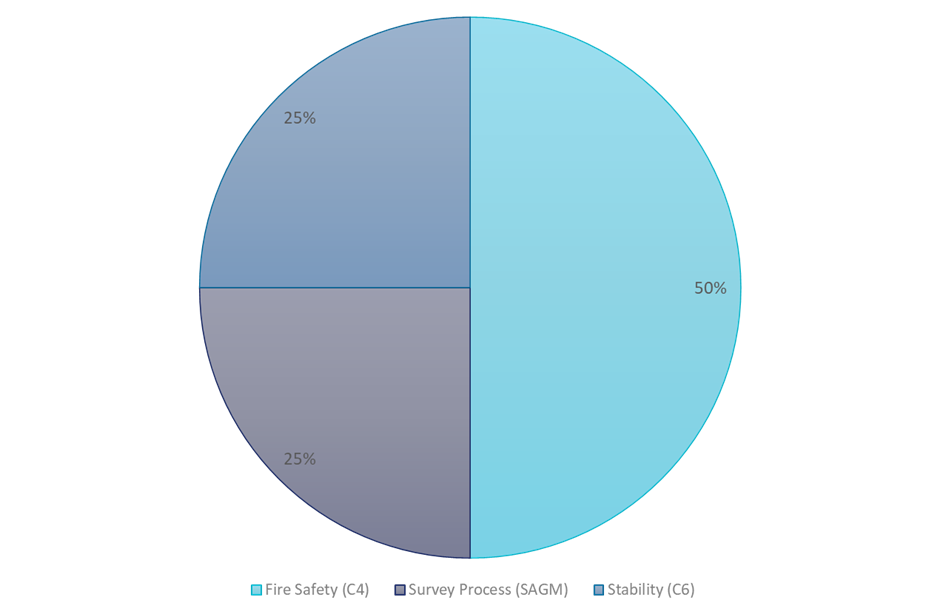

The pie chart below shows the percentage distribution of the findings identified during the Major Audits.

Compared to previous years, AMSA noticed a significant increase in major non-conformances (doubled) which jeopardises safety of personnel, the vessel or the environment and warranted immediate corrective action on the vessels or the surveyor’s survey practices. Some of the examples of major non-conformances identified include:

- Insufficient lifesaving appliances (Lifejackets, buoyant appliances etc.) for the recommended complement for passenger vessels.

- Incorrect lightship measurement recommended during periodic lightship check for passenger vessels, whilst the actual deviation in lightship has made the stability booklet invalid and triggered transitional surveys.

- Stability booklets approved with incorrect criteria thus allowing the vessels to operate while they failed to meet the correct stability criteria.

- Inadequate communication equipment for operation of vessels beyond LCS areas.

- Periodic lightship surveys not performed for passenger vessels over 12 meters and were incorrectly recommended with lightship declaration.

- Incorrect use of Temporary Operations Exemption. Some vessels which were issued with temporary operations following renewal/periodic surveys by the AMS had several major defects like damaged structural fire protection, damaged fire main/fire pumps, defective fire dampers etc, which were regarded as minor by the AMS to enable the vessels to operate.

In most cases, the surveyors promptly implemented the required corrective actions. However, in certain instances, AMSA, acting on the National Regulator's initiative, modified the certificates of survey for several vessels due to insufficient safety equipment for the complement they carry. These vessels had been deemed compliant by the surveyors despite lacking the necessary safety equipment.

During major audits AMSA identified multiple errors in periodic lightship checks conducted by various surveyors, where incorrect data was provided. In several instances, the deviations recorded in lightship data were significantly greater than the recommended values. As a result, transitional assessments were required, along with the development of new stability booklets.

In one instance, the surveyor promptly undertook the required corrective actions, including performing the inclining test and transitional surveys. However, in another case, the surveyor failed to implement the necessary corrective measures, leading AMSA, under the National Regulator's initiative, to revoke the vessel’s certificate of survey.

AMSA acknowledges and appreciates the numerous positive observations recorded during audits of several surveyors and we encourage surveyors to be self-motivated to strive for achieving excellence in surveying. This allows AMSA to perform the role of a modern regulator in a proactive way, through positive collaboration with the surveyors to achieve better safety outcomes.

Severe adverse findings – Surveyor counselled

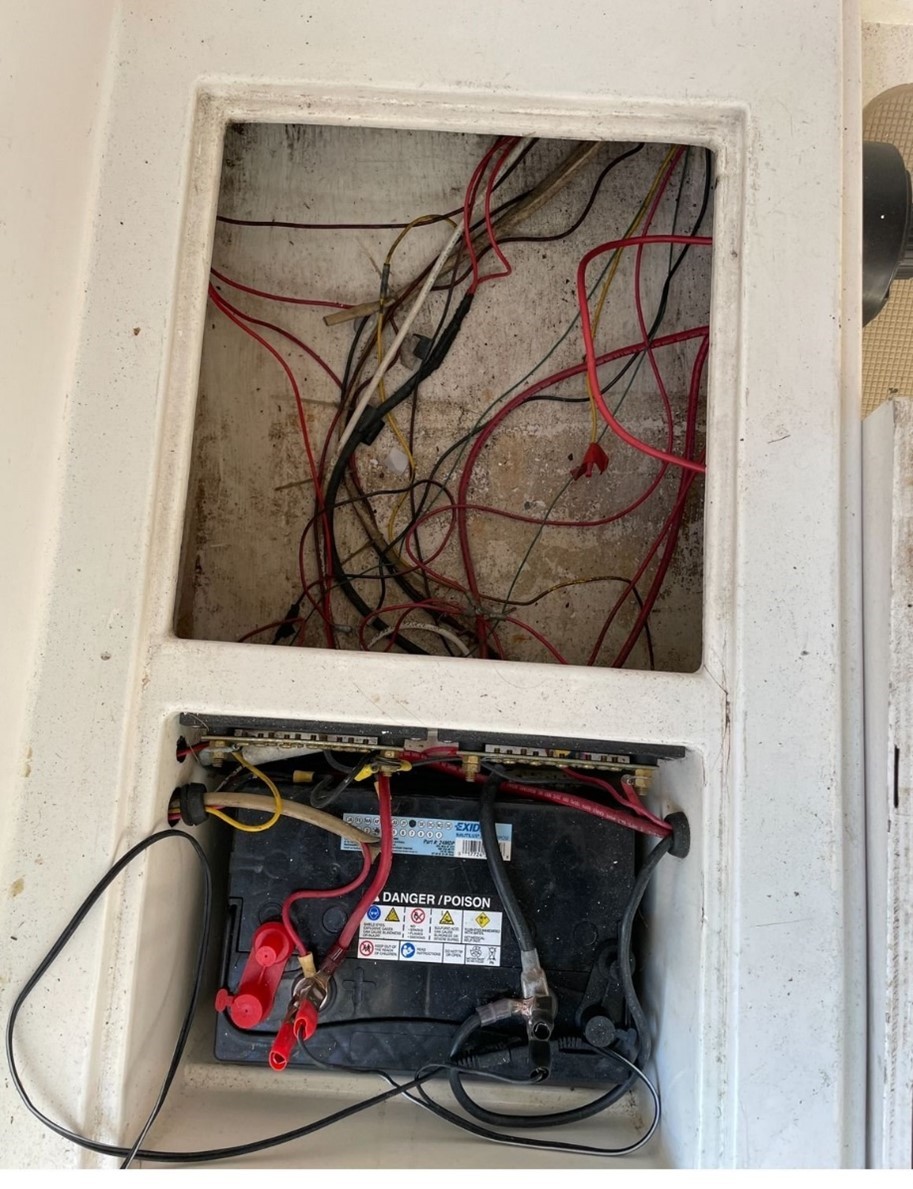

One of the major audits identified several serious non-conformances for which the surveyor took corrective actions as required. The surveyor was provided counselling advise due to a likely contravention of conditions of accreditation as per Sec.32, 33 and 35 of Division 3 of the regulations. Some of the major findings for this surveyor are listed below:

- Oil residue on the lagging of the engine room hatch on a Class 1B Passenger vessel resulted in an onboard fire. This vessel had been recommended as satisfactory by the surveyor during a periodic survey undertaken a short time prior to the incident. The vessel owner and AMS undertook corrective actions and defective lagging was replaced.

- Inadequate scale of critical communication equipment onboard two vessels for operations beyond LCS areas. Both vessels were recommended for operations in B waters following a periodic survey.

- One Class 1 vessel only carried 22 lifejackets, whilst the vessel was recommended by the surveyor to operate with 30 persons, including passengers, after the periodic survey.

- Insufficient buoyant appliances on board a 1D passenger vessel, which was recommended by the surveyor for higher passenger number. The surveyor failed to undertake corrective actions for this finding. AMSA varied the certificate of survey of the vessel on National Regulator’s initiative, following a show cause to the vessel’s owner.

Common audit finding - inadequate communication equipment

During the recent major audits, AMSA identified numerous instances of vessels being recommended by surveyors (and R.O surveyors) for operation beyond LCS areas without adequate scale of communication equipment (H.F radio or a satellite phone) during the commissioning and periodic surveys.

While some vessels were not installed with the adequate equipment, some of the surveyors weren’t aware of the equipment requirements and had failed to check the installation or function testing of a H.F radio. Guidance for testing of H.F radio can be found here.

Surveyors may require the owner to arrange for inspection and testing of radio equipment by a service technician if there is doubt of the equipment condition and functionality.

AMSA reminds surveyors to check the requirements of Marine Order 27 (Safety of navigation and radio equipment) 2016 or NSCV C7B 4.3 Table-2 or USL Code Sec.12 (as applicable) for the adequacy of the scale of communication equipment onboard all vessels.

⚠ IMPORTANT CORRECTION: An error has been identified with the AMSA901 form which did not permit the recording of satellite phone details. The error was identified through the audit process and associated feedback from surveyors.

The AMSA901 form has now been updated with tick box and a data entry field for the satellite phone section. Please see link below to access the updated AMSA901 form https://www.amsa.gov.au/forms/survey-report-and-recommendation. AMSA encourages surveyors to use the updated forms from the website when undertaking a survey.

Reminder – have your say on the surveyor accreditation scheme

Recently we invited surveyors to be a part of the industry reference group to review the surveyor accreditation scheme. If you would like to be a part of the review, please send an email to domesticsafetypolicy@amsa.gov.auwith a paragraph outlining your expertise, skills and experience and your interest in contributing to the review by 28 March 2025.

Survey Matters suggestions

- AMSA wants to make sure Survey Matters is relevant and useful for accredited marine surveyors, boat builders, class societies, and others involved in the survey of domestic commercial vessels.

- We encourage our readers to submit subject requests or ideas to DCVSurvey@amsa.gov.au for articles that would be of assistance to industry in future publications.