2025/01 — Sanctions

Sanctions

The purpose of this Marine Notice is to remind those who own, operate or are on board Australian ships, about offences under Australian sanction laws. It presents information prepared by the Australian Sanctions Office.

Purpose

The purpose of this Marine Notice is to remind those who own, operate or are on board Australian ships, about offences under Australian sanction laws.

This marine notice supersedes Marine Notice 05/2021.

Guidance for

- Ship operators

- Masters

- Officers Of the Watch (OOWs)

- Recognised organisations

- Flag states

Australia’s sanction laws

Sanction laws may, among other things, prohibit:

- the export or import of certain goods to or from certain countries, entities and individuals

- the provision of related services, including technical advice, assistance or training and financial services.

Offences arising under Australian sanction laws have extended geographical jurisdiction— category A status under the Criminal Code Act 1995 (Cth). This means the offences apply in a range of circumstances, including where conduct constituting an alleged offence occurs on board an Australian aircraft or an Australian ship, or by an Australian citizen outside of Australia.

For these purposes, ‘Australian ship’ is defined by the Criminal Code Act 1995 (Cth) to mean:

- a ship registered, or required to be registered, under the Shipping Registration Act 1981; or

- an unregistered ship that has Australian nationality; or

- a defence ship.

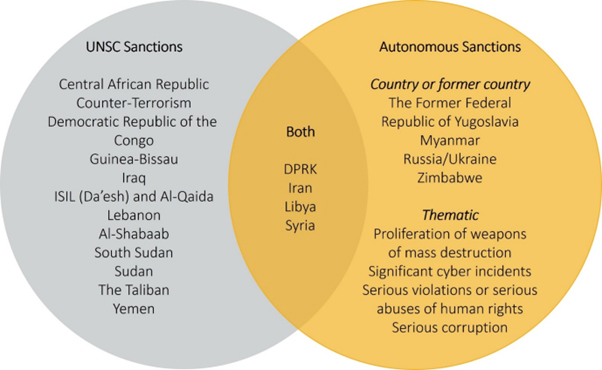

Australian sanction laws implement 2 types of sanctions frameworks - United Nations Security Council (UNSC) sanctions frameworks, which are binding under international law, and Australian Autonomous sanctions frameworks, imposed and implemented by Australia as a matter of foreign policy.

Sanctions frameworks are amended regularly. Full and current details of UNSC and Australian autonomous sanctions are available on the Department of Foreign Affairs and Trade (DFAT) website at sanctions.dfat.gov.au.

Australia currently implements the sanctions frameworks shown below.

Offences arising under Australian sanctions laws

Offences arising under Australian sanctions laws may apply to conduct that occurs on board an Australian ship, as well as conduct by Australians on foreign flagged vessels. It can be a criminal offence under both the Charter of the United Nations Act 1945 and the Autonomous Sanctions Act 2011 for an individual or body corporate to:

- make a ‘sanctioned supply’ of ‘export sanctioned goods’ or a ‘sanctioned import’ of ‘import sanctioned goods’ without authorisation, or

- to provide the services of an Australian ship to assist with, or in relation to, a ‘sanctioned supply’ or a ‘sanctioned import’ without authorisation.

| Punishment for individuals | Punishment for bodies corporate |

|---|---|

As at 1 July 2023, these offences are punishable by:

| As at 1 July 2023 these offences are punishable by:

For bodies corporate these are strict liability offences. |

Oil Price Cap (OPC)

Australia has joined the G7 in implementing 2 OPCs on Russian refined petroleum products. On 4 February 2023, G7 countries plus Australia agreed to OPCs of USD 100 per barrel for high value and USD 45 per barrel for low value Russian-origin refined petroleum products.

The OPC is applicable to all service providers, other than those who are designated persons or entities. The OPC aims to support stability in global energy markets while reducing the revenue Russia receives from refined petroleum products. This forms part of a comprehensive suite of measures Australia has introduced to impose costs on Russia for its illegal and immoral invasion of Ukraine.

Since 25 April 2022, due to the implementation of these 2 OPCs, Australia has prohibited by sea the import, purchase or transport of Russian ‘import sanctioned goods’ if the goods are exported from Russia (or a part of Russia) or the goods originate in Russia (regulation 4A of the Regulations).

Specifically import sanctioned goods for Russia include:

- ‘petroleum oils and oils obtained from bituminous minerals, crude' (Tariff Code 2709) as per item 9 of Schedule 1 of the Autonomous Sanctions (Import Sanctioned Goods - Russia) Designation 2022), and

- ‘petroleum oils and oils obtained from bituminous minerals, other than crude; preparations not elsewhere specified or included, containing by weight 70% or more of petroleum oils or of oils obtained from bituminous minerals, these oils being the basic constituents of the preparations; waste oils' (Tariff Code 2710) as per item 10 of Schedule 1 of the Autonomous Sanctions (Import Sanctioned Goods - Russia) Designation 2022).

On 4 December 2022, the Minister for Foreign Affairs issued a sanctions permit authorising the provision of Relevant Services if they assist with, or are provided in relation to, the import, purchase or transport of Russian oil and that oil was purchased at or below the OPC agreed between the G7 countries and Australia (USD 60 per barrel).

A sanctions permit is subject to the following conditions:

- All Permit Holders must notify the Australian Sanctions Office (ASO) Contact Point each time they intend to rely on this Permit, and

- This Permit may be amended or revoked at the discretion of the Minister.

A sanctions permit does not authorise the importation, purchase or transport of Russian oil, which are subject to separate prohibitions in the Autonomous Sanctions Regulations 2011 (Cth).

Permits can be revoked at any time by the Minister. Please refer to sanctions.dfat.gov.au for information relating to current permits.

Further information regarding the insurance industries’ requirement to submit voyage to voyage attestation measure can be found within the Oil Price Cap (OPC) Compliance and Enforcement Alert and ‘Coalition Statement on Price Cap Rule Updates’ which was published on 20 December 2023. Please refer to HM Treasury (UK) .

For further guidance regarding the OPC permit please see DFAT’s Oil Price Cap (OPC) Compliance and Enforcement Alert.

Further information

This document is explanatory only, does not have the force of law and does not in any way constitute legal advice. This document does not supplement or modify regulations made under the Charter of the United Nations Act 1945 or the Autonomous Sanctions Act 2011.

The Australian Government strongly recommends that those seeking to trade overseas consider obtaining legal advice in relation to Australian sanctions laws, as well as any other relevant Australian or foreign laws.

Australian Sanctions Office

The ASO within DFAT can provide general guidance but does not provide legal advice, nor can they provide specific advice regarding proposed or hypothetical activities.

Regulated individuals and entities are ultimately responsible for understanding their obligations and taking steps to determine whether a particular activity is compliant with Australian sanctions laws or requires a permit.

To contact the ASO, please email sanctions@DFAT.gov.au or submit an enquiry through the contact form via the Australian Sanctions Portal at pax.dfat.gov.au.